The Science of Dyeing

When we think about bringing newness to our product line, we use a variety of different approaches from introducing new silhouettes, new fabric platforms but also color.

1. Understanding Color:

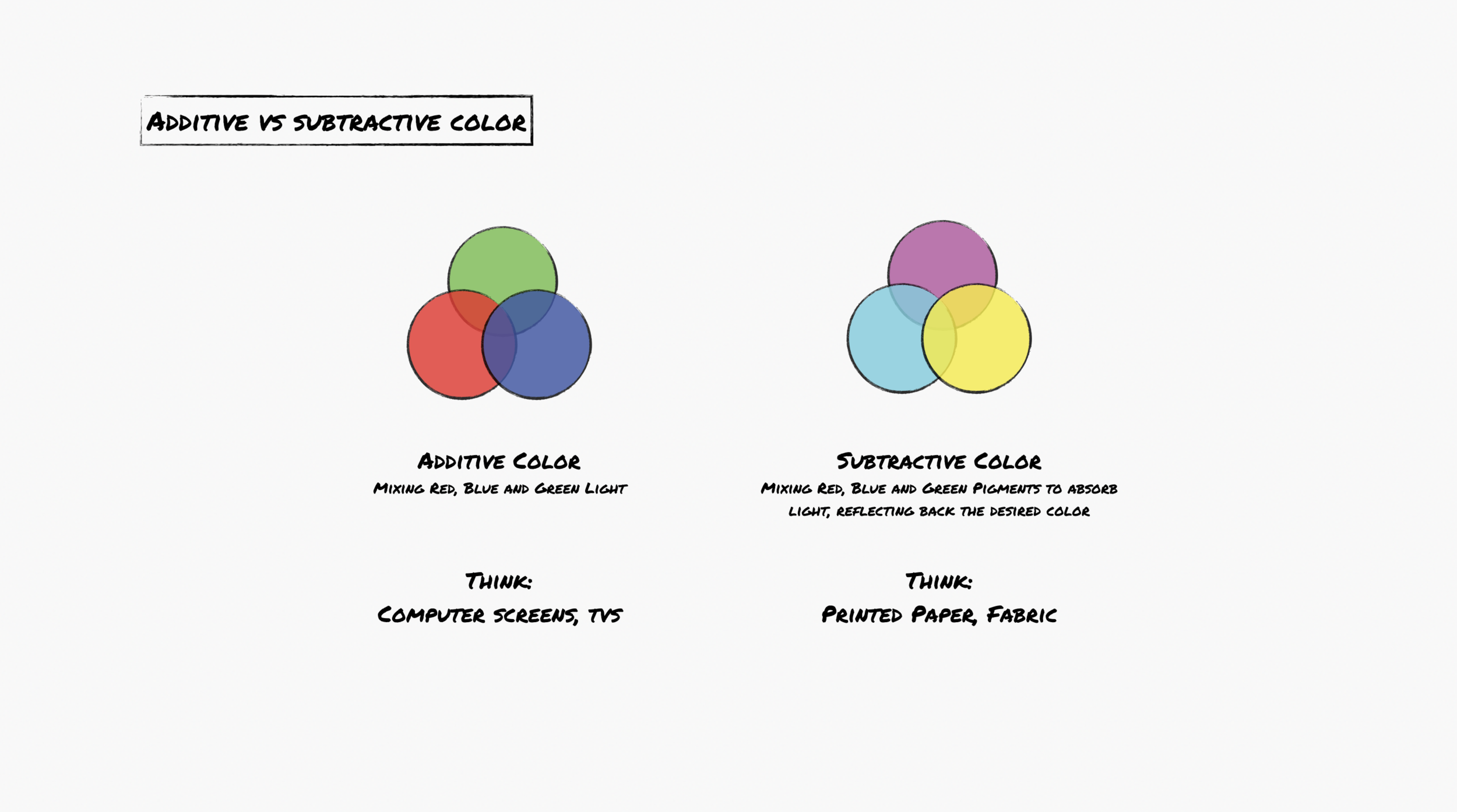

In general, color is created in two ways:

By mixing light - by mixing Red, Green, and Blue (RGB) light you can create a spectrum of colors. This is how your computer screen works.

By reflecting light - by mixing pigments like Red, Blue or Yellow (RBY)- or in the case of your printer Cyan (a light blue), Yellow, Magenta (Purplish-red) and Black (CMYK) you can create colors by reflecting back only certain wavelengths.

2. Lab Dips - How we choose our color:

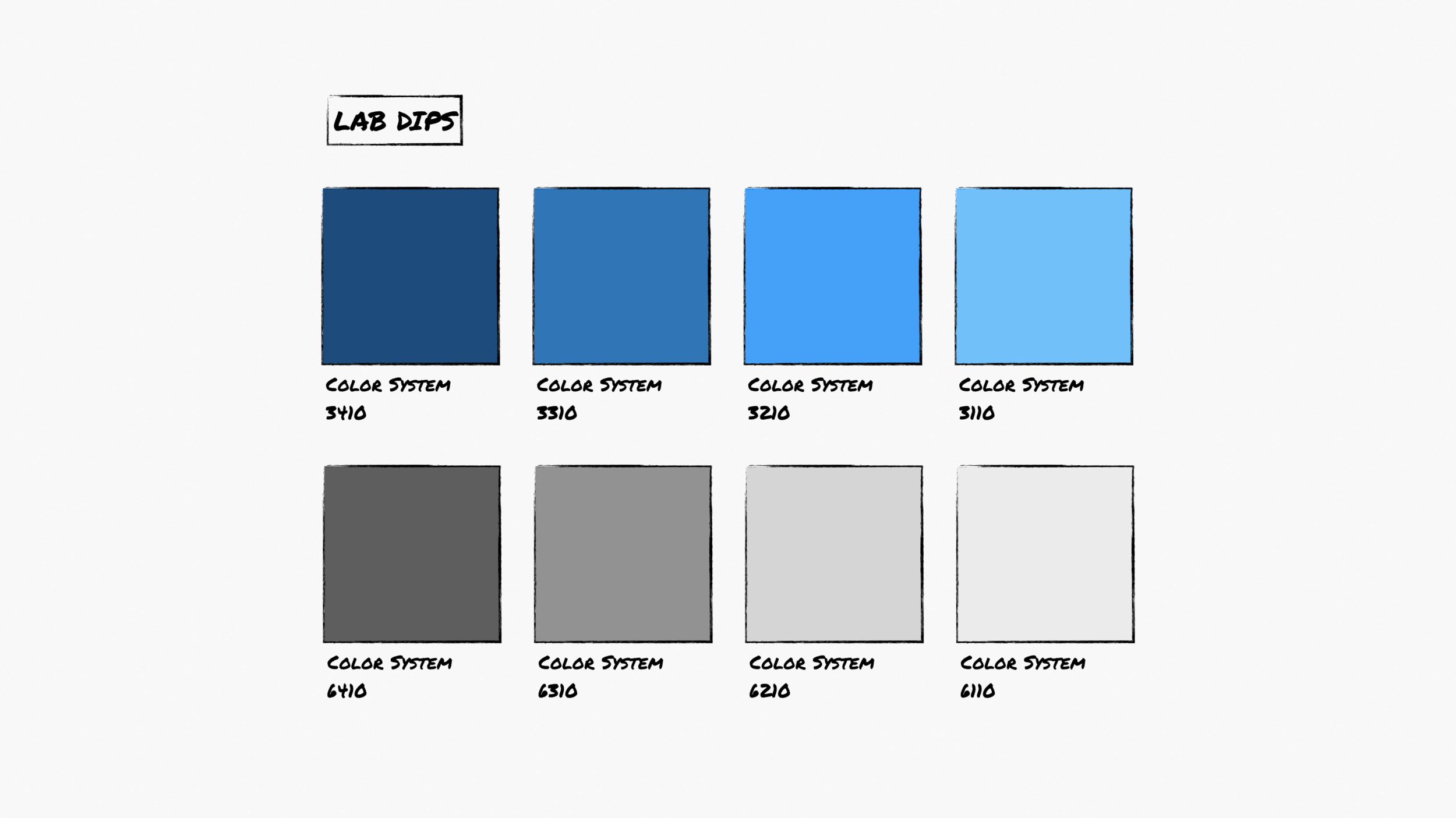

Blues and Grays with Neutrals is the core of our color palate - but hitting that color requires experimentation, and this is done through a Lab Dip.

We submit reference swatches or a Pantone Number (A color system, with ones specifically for fabrics - but similar to the color card at a paint store).

Our factory creates 3 different blends of dyes in the lab, and “dips” our fabric in the dye.

We choose which sample meets our intended palette. Looking at two things:

HUE: The “Color” of the dye - does it lean, Reddish, Greenish, Yellowish or Blueish?

SATURATION: The “Volume” of the color - bright colors are “Saturated” and others are “Muted” our in the past our colors have been more muted for versatility (if the colors aren’t too bright, it’s harder for them to clash) - however, we are starting to experiment more with deeper saturation - particularly “Indigo”.

3. Ways of Dyeing:

Dyeing is a coloring process where you steep fabric in a solution full of a colorant.

Piece Dye: Piece dyeing is when raw fabric (called greige *gray-je* - as it often looks grey or beige) is dyed giving consistent dye for the fabric. Used in: Most of our product

Yarn Dye: This is when yarn is dyed, and then woven or knit with other yarns to create patterns. Used in: Aero

Garment Dye: This is a type of dyeing process where a finished garment, is dyed as a whole. The result is softness from the boiling process, and color variation at the seams.

4. Different Dyeing Processes.

To dye the fabric there are different processes to get the dye to penetrate the fiber there are different techniques we use.

Solution Dye

This is the most common type of dyeing process, it’s very similar to the RIT Dye that you can purchase in a store. It is a pigment that is dissolved in water, and is relatively cheap - but uses a lot of water.

Each fiber is different and absorbed dye differently. Salt or an Acid can be added for different fabrics like Polyester, Nylon, and Cotton to help pull the dye in.

Used in: Most of our garments are done this way and is versatile and cost-effective

Cationic Dye

Cationic dyeing allows us to selectively dye yarns - achieving the look of a yarn dye, but with the volume and versatility of solution dyeing.

A fabric is knit or woven with alternating yarns of regular polyester, and “cationic” polyester - basically positively charged polyester.

When the fabric is dyed - a cationic dye or charged dye only binds to the cationic polyester, leaving the other yarn in most cases white or its original color.

Used in: Apollo Heather, Kinetic Heather

CO2 Waterless Dyeing

This is a new dyeing process that instead of using water as the solution, uses carbon-dioxide - the reason for this is that it is easy to separate the dye afterward and re-use the CO2 for future dyeing. This is significantly more sustainable as it reduces the heat needed to boil water, and also cuts down on wastewater runoff.

You can learn more about this process in detail in our article on Waterless Dyeing

Used in: Doppler, Mercury Shell Fabric.

Pigment Dye

Another way of reducing water consumption in dyeing is to not dye at all. With pigment dyeing, the pigment - the pure color compounds - are blended directly into polyester yarn as it is being extruded.

Think of the vegetable-flavored pasta - where the color is given by carrots and spinach - it’s the same concept.

We don’t use it yet but will consider for fabric where we want rich, and highly saturated colors - like black or navy and it's EXTREMELY colorfast.

Hope this gives some “color” to how our garments are made!