How Waterless Dyeing Works

Solvents are needed in dyeing

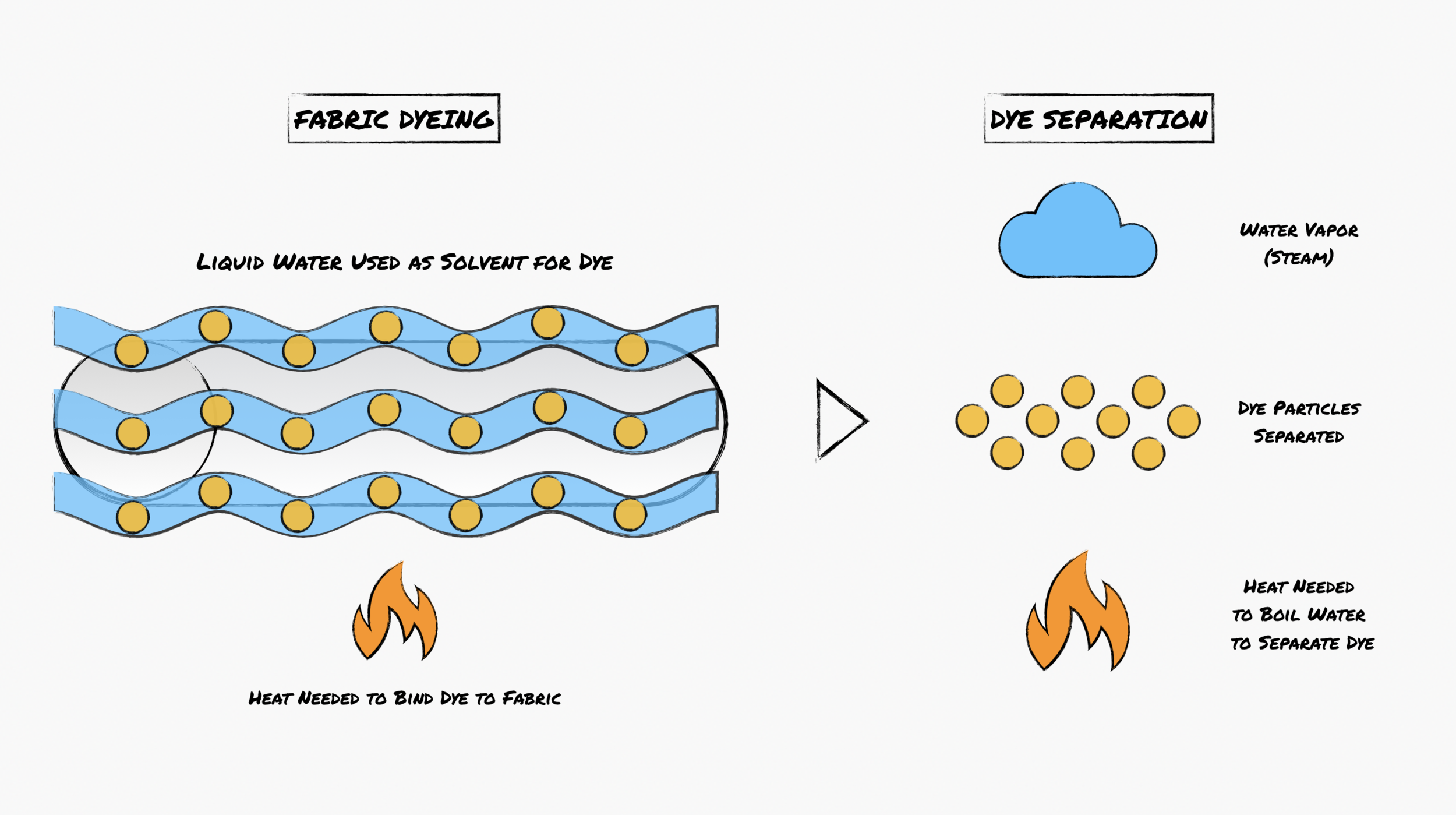

In order to give fabrics a variety of colors, we use dyes. But to get the dye particles to penetrate the fabric completely, we usually need a material to carry the dye through out the fabric easily, and this is called a solvent.

Separation of solvents through boiling

One of the most common solvents used for painting, dyeing and other chemical reactions is water, due to it’s abundance. The challenge is after the reaction is complete, how do we separate the unused dye particles from the solvent? Typically, this is done through a process of of distillation where the solvent is boiled off, leaving the dye behind. This is similar to how alcohol spirits are separated from the fermented solution that contains water.

Dyeing of fabric (grey tube) with dye particles (yellow dots) with a solvent (blue water) of and their subsequent separation

Boiling hundreds of gallons of water, however, is very energy intensive, and would waste excessive amounts of fuel or electricity, while filtration requires significant power as well to run high-pressure water pumps.

Harnessing different phase change points of Water and Carbon Dioxide

Because we are focusing on "boiling" - the process of separating a dye from it's solvent by turning the solvent from a liquid to a gas - the boiling point is a function of pressure and temperatures. With this in mind we can harness the unique boiling points of carbon dioxide, by using “supercritical” carbon dioxide which is more liquid than gas at high temperatures.

At room temperature and atmospheric pressure (sea level pressure), water is a liquid and carbon dioxide is a gas. However, at high pressures, carbon dioxide can become “supercritical” and become a liquid.

So instead, we can use carbon dioxide as our solvent, by pressurizing it during the dyeing process, and releasing that pressure to turn carbon dioxide into a gas, without using expensive thermal energy to boil, instead using lower energy usage pneumatic compressors.

Dyeing of fabric (grey tube) with dye particles (yellow dots) with a solvent (turquoise carbon dioxide) of and their subsequent separation

When the carbon dioxide is separated, instead of releasing it into the atmosphere, it can be recycled nearly infinitely for the next dye lot.

A low energy, waterless dyeing process

Carbon dioxide, waterless dyeing circumvents the need for large amount of water use, boiling or filtration - but it requires some complex machinery. Fortunately, we’ve partnered with Singtex, a leader in clean dyeing procedures for performance fabrics and have been able to use this process in our Mercury, Dry Days and Responsive fabrics.