The Evolution of Polyester

Polyester is a polymer invented in the 1950s, and much like other inventions, it has evolved and improved significantly over the past seven decades. The once slick and stiff fabric has evolved into a high-performance, premium material with a much lower ecological footprint due to innovations in fiber shape, sizing, and spinning.

We highly suggest reading this article, by Marc Bain - a Quartz writer who’s been following the performance market closely - who gives an overview of the role of performance fabrics in the apparel industry.

Polyester Then

What are the misconceptions of polyester today?

When polyester appeared in apparel in the 60s and 70s, it became associated with a few challenges.

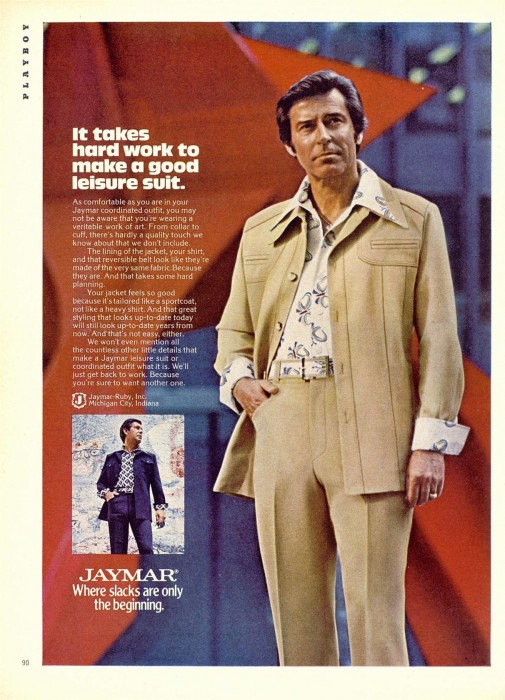

The 70s aesthetic: It’s the hot, double-knit leisure suit of the 1970s that my grandfather wore

Doesn’t feel natural: It’s synthetic so it’s not eco-friendly

It’s uncomfortable: It’s hot & smelly & slick

Figure 3: “Leisure Suits” of the 1970s… they were made of a thick, double-knit fabric which contributed to their “hot” perception and were quite shiny.

Why do we use polyester in the first place? Polyester has many benefits:

Shape resilience (doesn’t shrink)

Wrinkle-resistance

Moisture-management

Machine-washability

It’s not about cheapness, it’s about the right material for the right application. Aluminum may be cheaper than solid gold, but a solid gold laptop isn’t necessarily better because it would be so much heavier and would dent easily. Cotton & Silk may be more expensive - but we don’t necessarily believe they’re the right.

A Brief history of Polyester:

1951: Dupont invents Polyester (known as Dacron)

1970s: "The Leisure Suit" comes and goes, giving a polyester a bad reputation for a generation (primarily Baby Boomers) See Image above.

1990s: Development of performance polyester with new cross sections and geometries

1996: Dri-fit first appears in US Olympic Uniforms

2000s: Polyester (yarn) production centralizes in China / East Asia (why we’ve focused our fabric supply chain there)

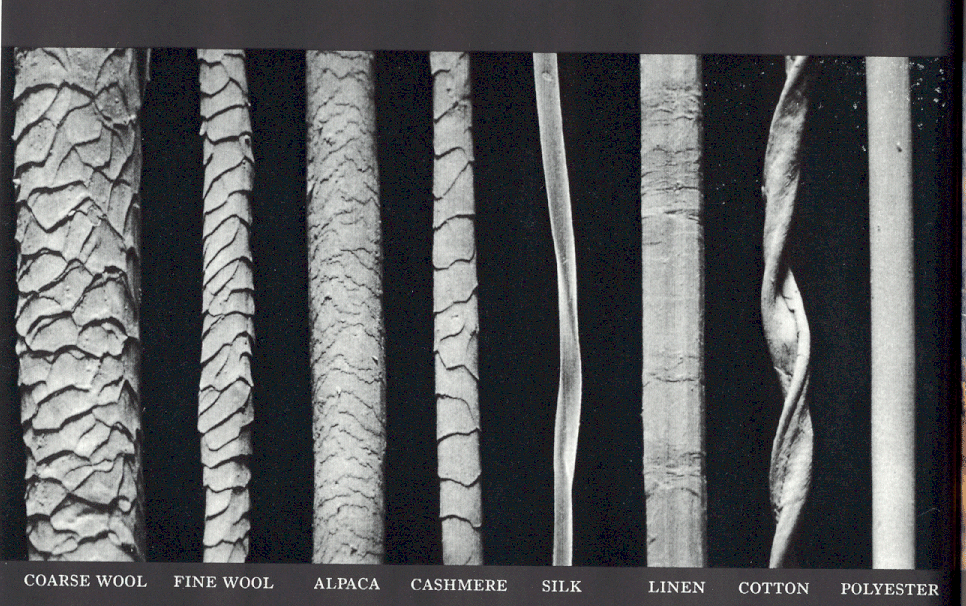

Figure 2. Cross micrographs of different natural fibers compared to polyester. Polyester is in many cases finer than “natural” fibers. The original form of polyester in it’s tubular form is shown here.

Polyester Now

Polyester production has increased significantly over the years, and with improved equipment and expertise.

Polyester fiber shapes have changed dramatically: Initially in the 70s, most polyester was a tubular shape, giving it a slick hand-feel and a shiny appearance. New cross sections such as H, Star, X, and Triangle shaped cross sections emulate other natural fibers, and deflects the light instead of bouncing it back like a mirror.

Ecological Footprint: Polyester actually can have a lower eco-footprint than cotton with respect to water and land use, particularly when using recycled polyester.

Recycled Polyester: We use recycled polyester in our Atlas socks, Responsive Tees, 3DPK Merino and several other garments which lowers our virgin polyester consumption.

Brushing and spinning processes give natural hand-feel: We brush some of our fabrics such as the Aero interior creating a softer, cotton-like hand feel.

Spinning: Yarns spun out of individual polyester fibers emulates how cotton is made - we use this in the Pace Chino to give it a cotton-hand and refracts light a for a matte aesthetic.

Recycled origins: Cotton and Polyester each have their own challenges in terms of production - cotton is highly water and land intensive while polyester does require energy for processing. However, polyester actually has a lower eco-footprint than cotton, particularly when using recycled polyester. We use recycled polyester in our Atlas socks, Responsive Tees, 3DPK Merino, Mercury Jacket and several other garments which lowers our virgin polyester consumption.

Odor control: New treatments such at Zn+ prevent microbial growth and coffee grounds absorb odors once they're created. In some cases, the performance is actually better than natural fibers.

Figure 4: A variety of new polyester cross sections - no longer limited to simple tubular shapes, and can more closely resemble wool, linen and cotton affecting hand feel and a matte aesthetic. (Dhamija et al)

Polyester has evolved significantly, through manufacturing techniques and material design to create fabrics that are easy to take care of, manage moisture, and are quite durable. We believe that synthetic fibers and natural fibers each have their own properties that allow them to serve different use cases, and in many cases work well together to create increasing levels of performance for everyday clothing.