Waterproof Breathable Testing Explained

We use a variety of waterproof / breathable membranes in our outerwear, and they commonly have a rating associated with them often listed in the form of:

Waterproofness: mmH2O / Breathability: mLH2O/m2/24hr

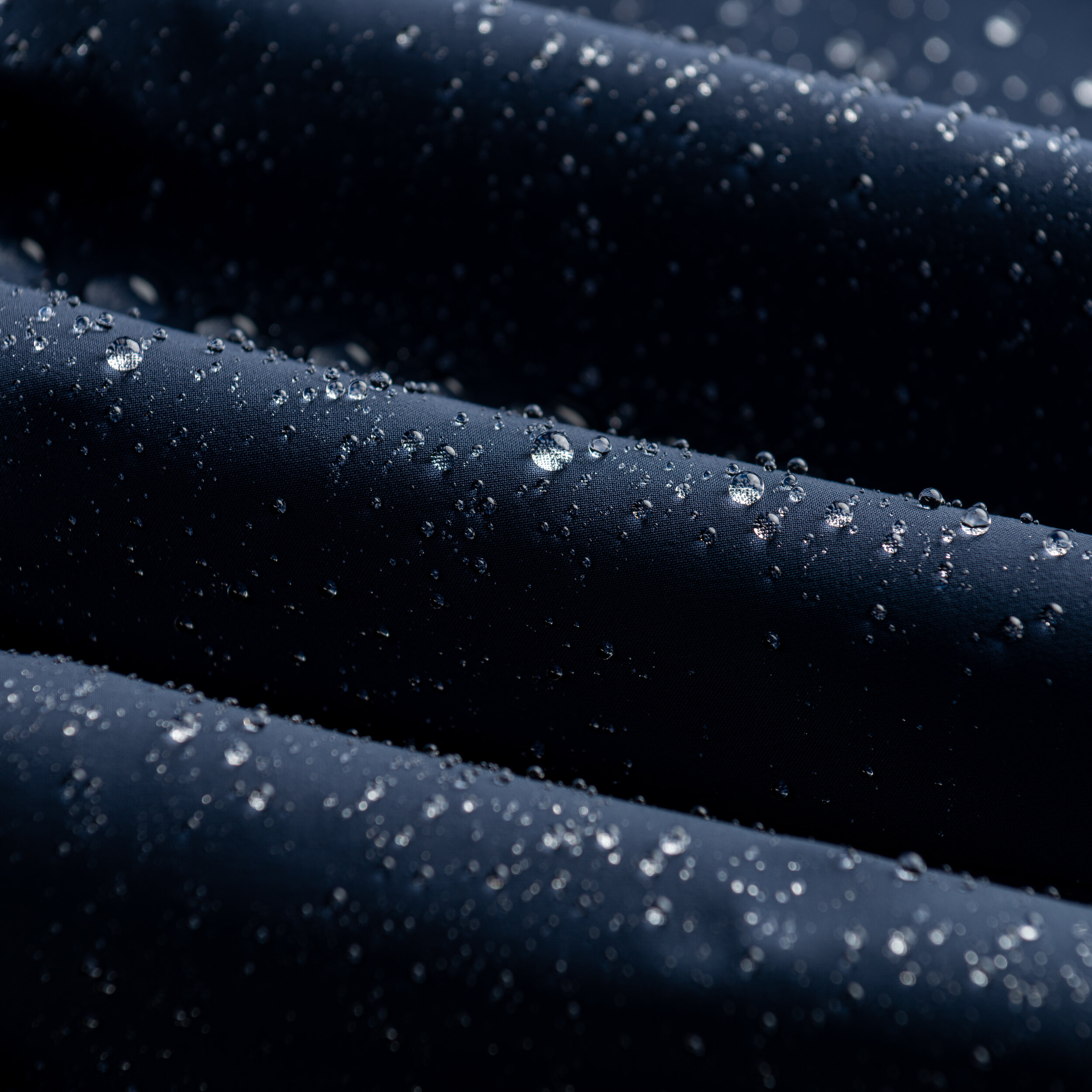

Hydrophilic, non-porous Polyurethane is our common membrane as it’s breathable, waterproof, stretchy and durable.

Waterproof and Breathable?

But how can something be Waterproof and Breathable? This is possible due to the fact that water in gaseous form (steam) is a single molecule, while it’s liquid form aggregates to create large droplets. A porous membrane (like PTFE) has small pores that are big enough for steam to pass through, but too small for droplets. Alternatively, a hydrophilic, non-porous membrane (PU) can also be used, which is impermeable to liquid water, but can pull individual droplets through, do to the polarity of the polyurethane.

Waterproof Rating

The measure of how waterproof something is is described in terms of the pressure of a column of water above a fabric, before a water droplet will penetrate through the membrane.

This height is called “Hydrostatic Pressure” as the water at sea level exerts a certain pressure due to gravity - and the higher the water level, the more waterproof a fabric is.

Breathability Rating

When we perspire - or sweat - our sweat evaporates and turns into steam. That evaporation is a key part of keeping us cool, and so it’s important for a fabric to breathe - as a humid microclimate causes ineffective cooling. The measure of breathability is meant to simulate how much moisture can pass through a fabric.

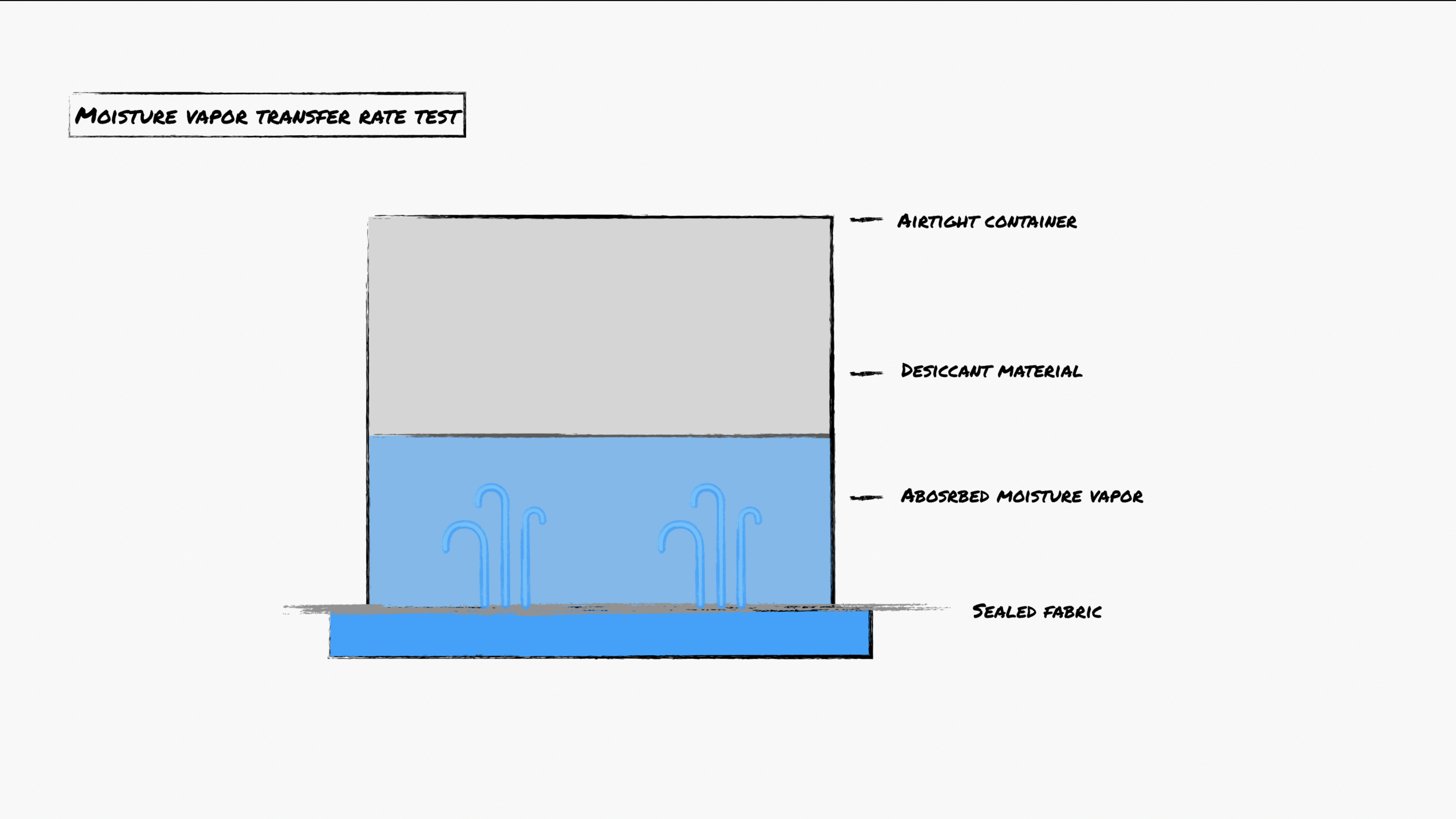

The test schematic for ASTM E96

This passage of steam (gaseous sweat), is quantified by measuring the volume of water that can pass through a region of fabric over a specified length of time. In this case, a airtight container is filled with a desiccant - a material that dehumidifies - and covered with a the fabric to be tested. It’s then put in contact over a plate of water - and over a period of time the volume of water gained into the vessel is measured. This gives us mL / square meter of fabric per day.

These stats for each product are important measures of the performance of waterproof breathable fabrics, but are not the only factor - where stretch and durability must also be considered.