Garment Testing for Easy Care

While garments are subject to abrasion, rubbing and all sorts of use during the day, the most significant wear-and-tear on a garment occurs during the wash and dry cycles. Mechanical agitation, exposure to moisture and hot environments can accelerate the conditions that cause seams and materials to break down over time.

1. Fabric Selection & Testing

Ease of care can be designed into but it has to start at the fabric development and selection stage. We look at two things: Composition and Construction. Fundamentally, materials which contain cellulosic (cotton, viscose) yarns will tend to shrink due to hydrogen bonds created during the wash/dry cycle, while protein-based yarns (wool) can be susceptible to heat deformation. These can be stabilized by fibers like polyester which have a shape memory effect when exposed to heat . The construction of the fabric also dictates how stable the fabric is - jersey knits are mostly likely to shrink, and wovens to wrinkle and warp-knits are somewhere in between. We select fabrics knowing how the composition and construction can effect the end care and design around that.

A fabric testing report for our Fusion Fabric.

When selecting a fabric, we often work with third-party testing or mill-provided testing reports to understand how the fabric will react to pilling, abrasion and washing to help us decide if it’s the right fabric to use from the beginning.

2. Prototyping

During the prototyping process, we wear and wash test the garments to get a sense of how a sewn garment will react. This helps us optimize seams and panel orientation to control dimensional changes and determine if pre-shrinkage is needed, or stabilization with interfacing is needed in other areas.

A typical wash testing report during our development process.

This washing of the prototypes is a critical process, and Sherri who heads up our product development, ensures each product has a thorough analysis - after a “boil and burn” wash cycle to put the garment through the toughest cycles.

3. Pre-Production

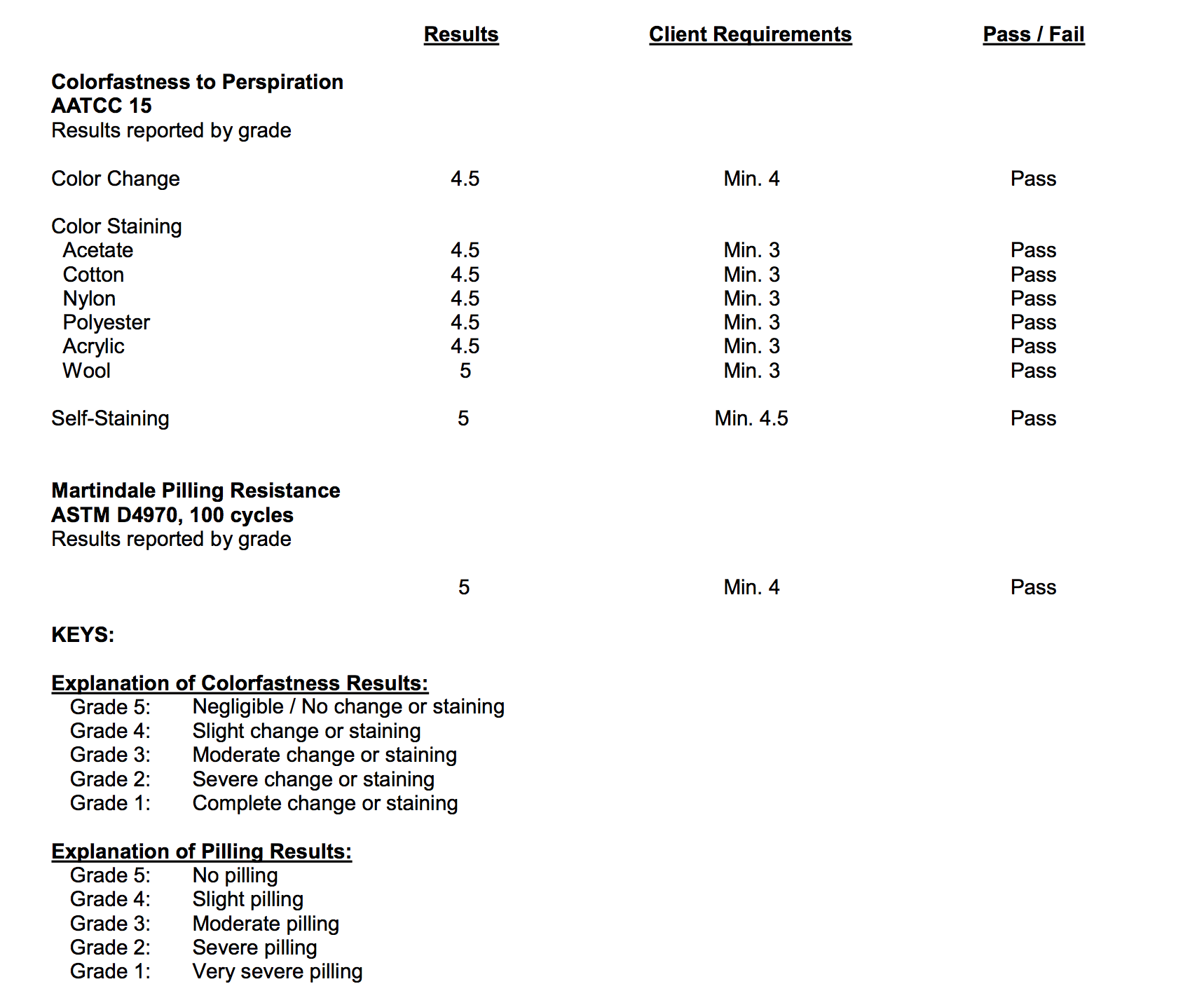

When a product is ready for production, one of our final reviews is a full garment test report to develop our care instructions. We use third-party testing using ASTM (American Society for Testing and Materials) and AATCC (American Association of Textile Chemists and Colorists) testing standards for:

Dimensional Stability to Wash and Dry Cleaning

Colorfastness during Washing and Dry Cleaning

Colorfastness to other solvents

Pilling and Abrasion

Below, you’ll find a typical garment test report - in this case for our Aero Shirt - which allows ensure that our products meet our standards for ease of care.

The Testing Report

Colorfastness during Washing

Dimensional Stability during Washing

Colorfastness to Perspiration and Abrasion Testing