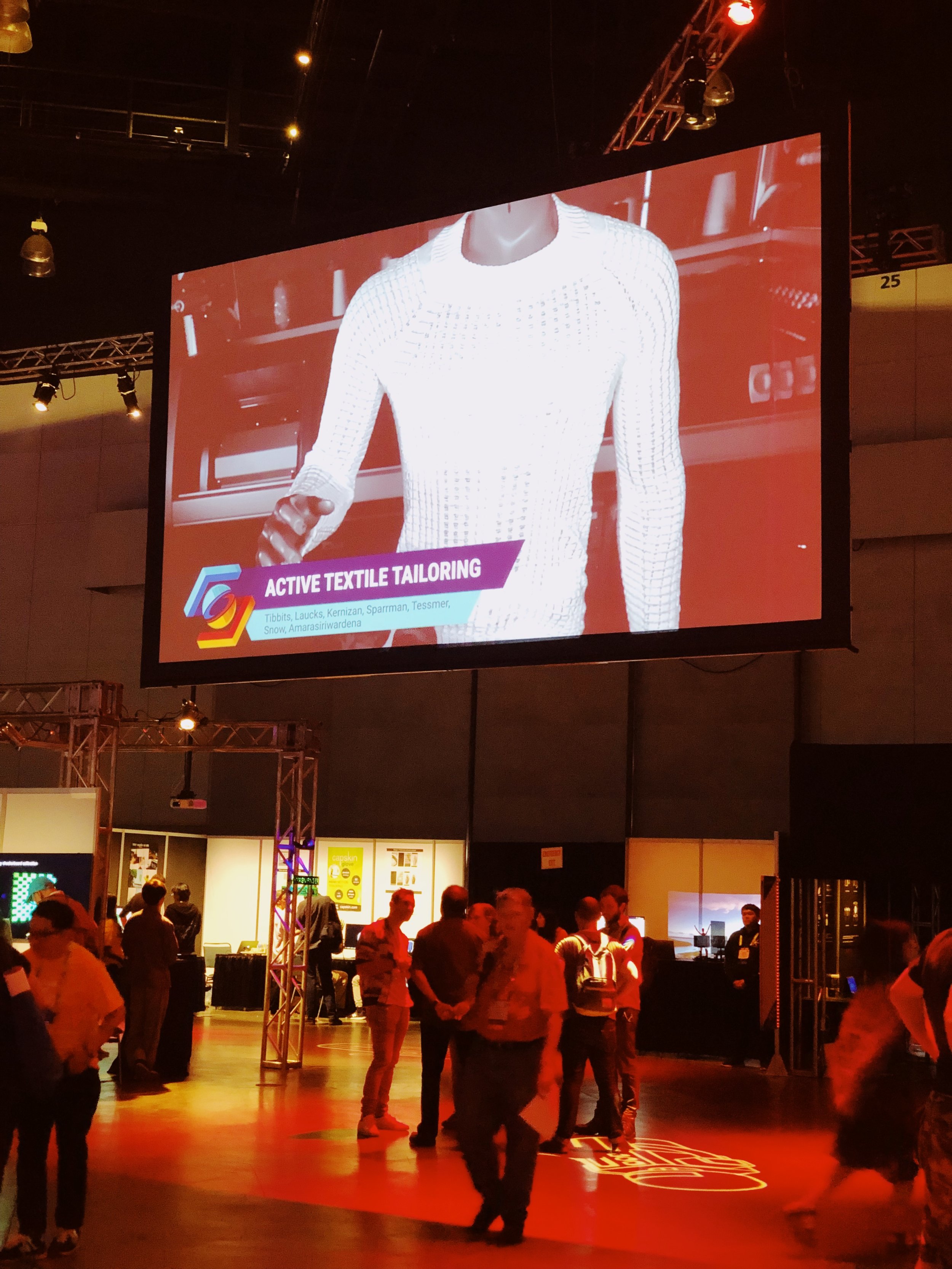

Active Textile Tailoring at SIGGRAPH

For the past two years we’ve been working with the Self-Assembly Lab at MIT to develop Active Textile Tailoring. This process utilizes new and familiar fibers in novel ways to create fast, post-production tailoring through computerized knitting and computer-numerically-controlled robotic activation.

As part of our AFFOA research, with the team from the Self-Assembly Lab, we had our first public demonstration of the Active Textile Tailoring process at SIGGRAPH - the premier computer graphics conference.

Active Textile Tailoring

Active Textile Tailoring brings together three processes that allow instant, personalized garments.

Thermoresponsive and Non-Active Yarns. Synthetic yarns change length with heat exposure that are contrasted with non-active natural-fibers.

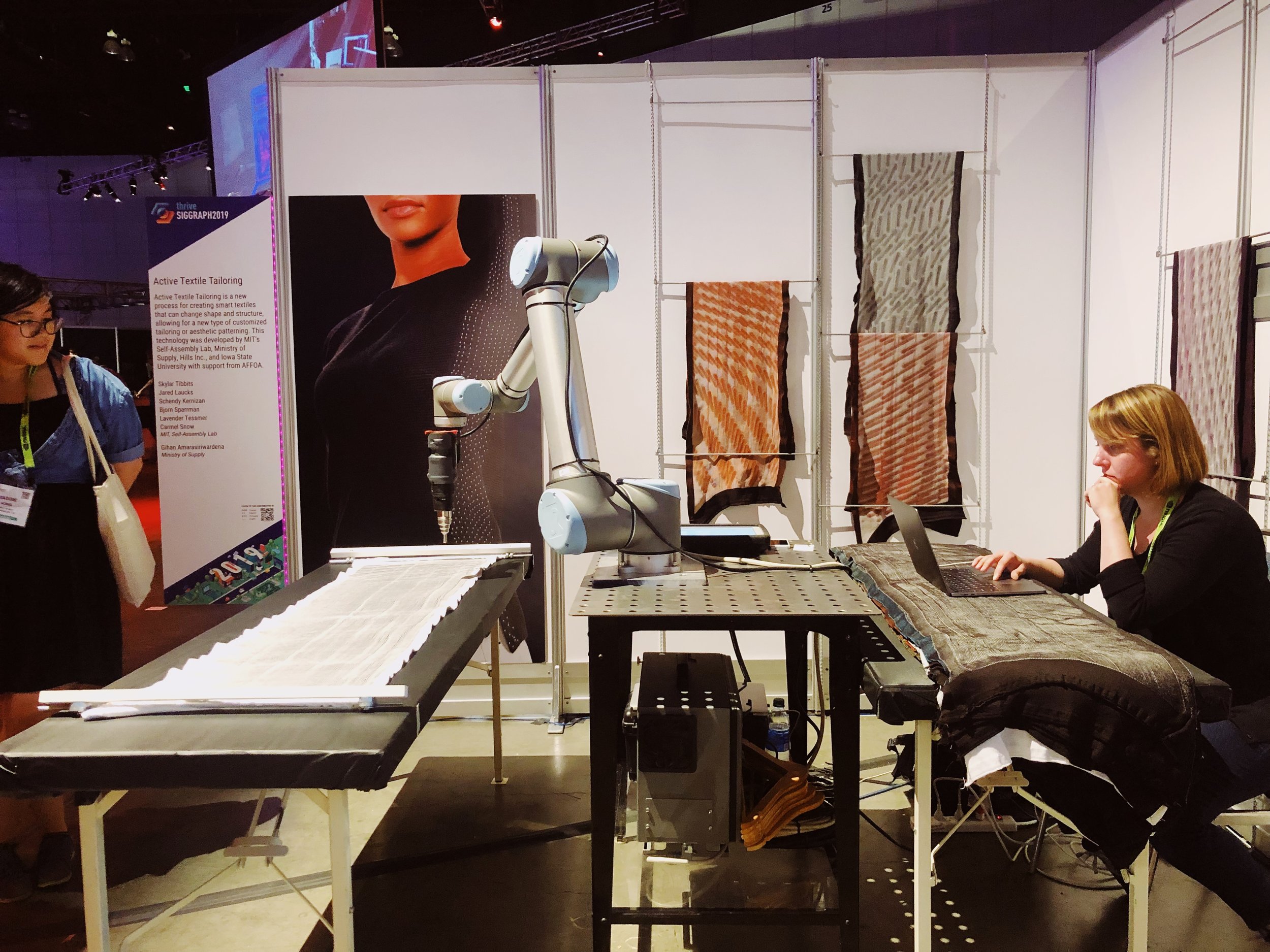

Computerized Knitting. Flatbed knitting allows the ability to create intricate and specific fabric structures that harness the dimensional change of the active yarns.

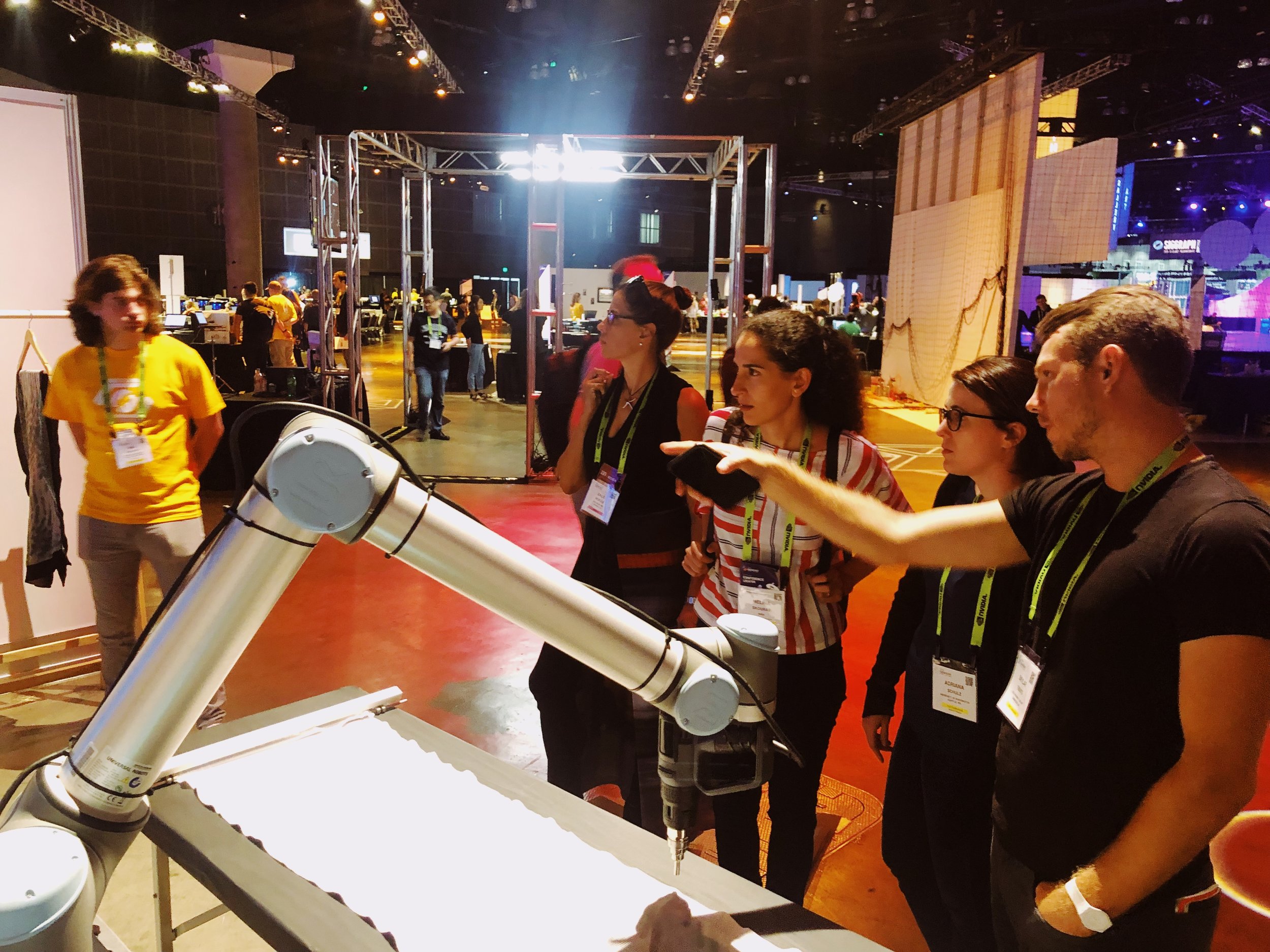

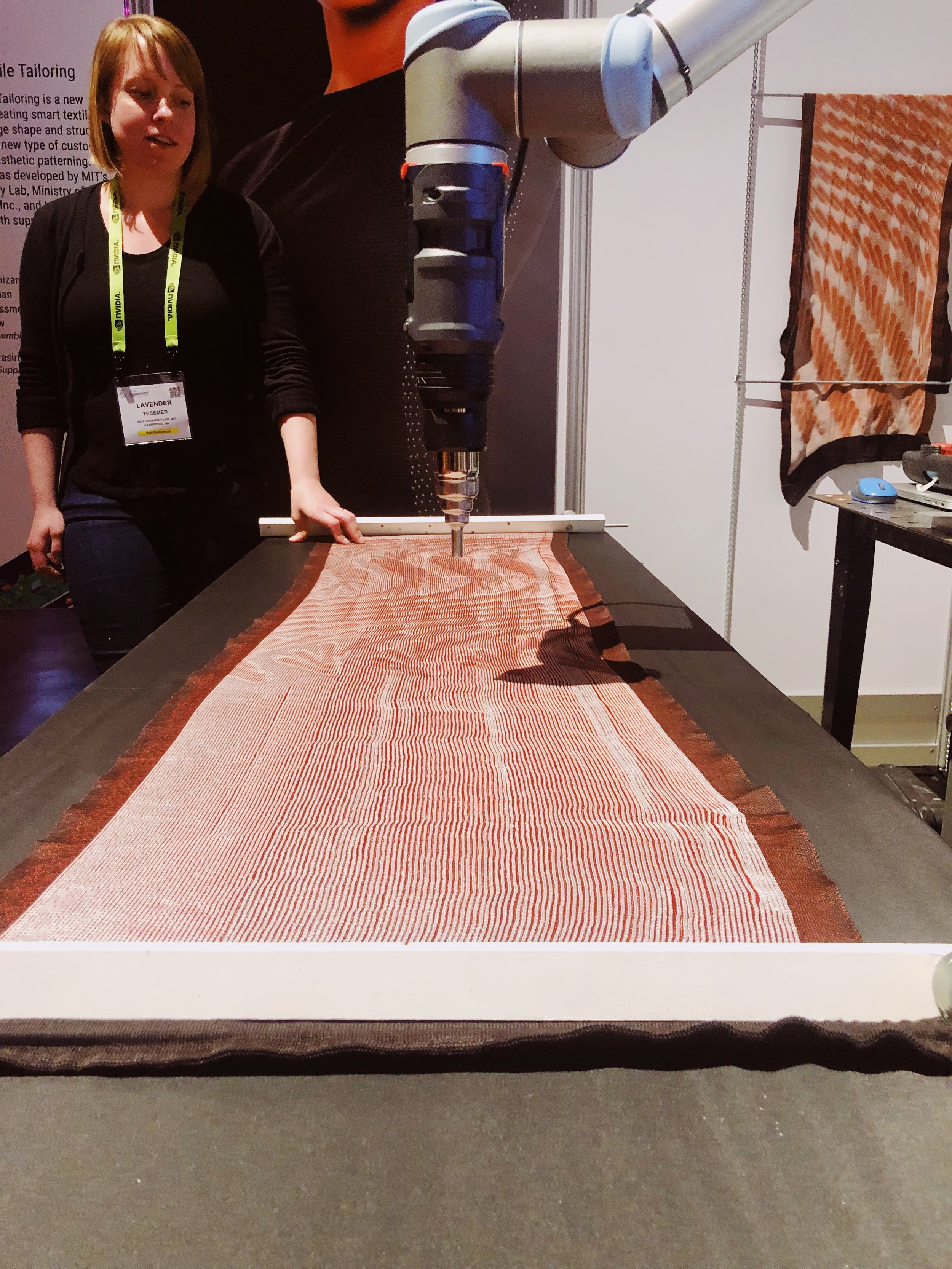

Robotically-Controlled Heat Activation. A robotic arm follows a tool path that heats fabric in specific areas to achieve the desired fit, design or functionality.

The process uses familiar, readily available yarns including Cotton for a soft hand feel and is activated at a temperature that stabilizes it for machine washability. We’re developing three different applications of this technology.

1. Custom Design.

Robotic activation, allows rapid personalization of garments and accessories with virtually any vector-based graphic in minutes.

A robotic arm follows a beautiful mathematical path, that can render millions of permutations with the change of a few parameters.

A controlled tool path can create elegant brush strokes on fabric, shown here on this scarf.

2. Custom Fit.

Garments can be instantly tailored from a standard size to a custom fit, by using body measurements and creating a unique tool path. This allows alterations to be done in a matter of minutes, particularly with knit garments which aren’t typically tailored.

Left: A stock-size garment. Right: The same stock-size garment after Instant Tailoring.

3. Custom Functionality.

We also see custom functionality as an application where custom ventilation and other attributes can be applied through robotic activation of the fabric.

Ventilation and opacity can be controlled through Active Textile Tailoring.

This live demonstration was the first pilot in our pursuit of greater personalization and customization of the aesthetic, fit and function of our garments. Below are more behind-the-scenes from the conference.

ACTIVE TEXTILE TAILORING TEAM:

Ministry of Supply:

Gihan Amarasiriwardena, Aman Advani

Self-Assembly Lab, MIT:

Lavender Tessmer, Carmel Snow, Sophie Richter, Schendy Kernizan, Jared Laucks, Skylar Tibbits

Mechanosynthesis Group, MIT: John Hart

Iowa State Team:

Rui Li, Guowen Song

Hills Team:

Tim Robson, Jeff Haggard

Funded by AFFOA